Twin Screw 5-Rollers Calender Extruder Spc Floor Equipment

$195000-235000 /Set/Sets

| Payment Type: | L/C,T/T |

| Incoterm: | FOB,CFR,CIF,EXW |

| Min. Order: | 1 Set/Sets |

| Transportation: | Ocean |

| Port: | SHANGHAI |

Mr. TONY

What can I do for you?

$195000-235000 /Set/Sets

| Payment Type: | L/C,T/T |

| Incoterm: | FOB,CFR,CIF,EXW |

| Min. Order: | 1 Set/Sets |

| Transportation: | Ocean |

| Port: | SHANGHAI |

Model No.: HBZ-110/220

Brand: HAOBANG

Place Of Origin: China

Status: New

Product Category: Plastic Sheet

Video Factory Inspection: Provided

Mechanical Test Report: Provided

Marketing Type: New Product 2020

Core Component Warranty Period: Not Available

Core Components: Engine, Bearing, Gearbox, Motor, Pressure Vessel, Gear, Pump

Warranty Period: 1 Year

Core Selling Point: High Productivity, Accurate Temperature Control, Competitive Price, Famous Brand Motor, High Safety Level, Energy Saving, Automatic

Out-of-warranty Service: Video Technical Support, Online Support

Applicable Industry: Manufacturing Plant

Where To Provide Local Services (in Which Countries Are There Overseas Service Outlets): None

Showroom Location (in Which Countries Are There Sample Rooms Overseas): None

Voltage: 380V/3P/50HZ or as local voltage

Key Selling Points: Multifunctional

Operator: 1-2 persons per shift

Transport Package: PE Film and Wooden Package

Machine Control: SIEMENS PLC

Color: Customer Choice

| Selling Units | : | Set/Sets |

| Package Type | : | We use PE film for packing or pack it according to customers special request. |

Twin Screw 5-Rollers Calender Extruder SPC Floor Equipment

WHAT IS SPC FLOOR

SPC floor is based on high-tech development of a new type of environmental protection FLOORING, with zero formaldehyde, mildew, damp, fire, insect control, installation simple features.

In Europe and the United States developed countries and Asia-Pacific market wide popularity.

Rely on its outstanding stability and durability, SPC floor solved the problem that real wood floor damp to be out of shape and mildew to rot, had solved the formaldehyde problem of other decorate material.

The design and color pattern that it can choose is numerous, apply to fit for public place such as indoor outfit, hotel, hospital, mall.

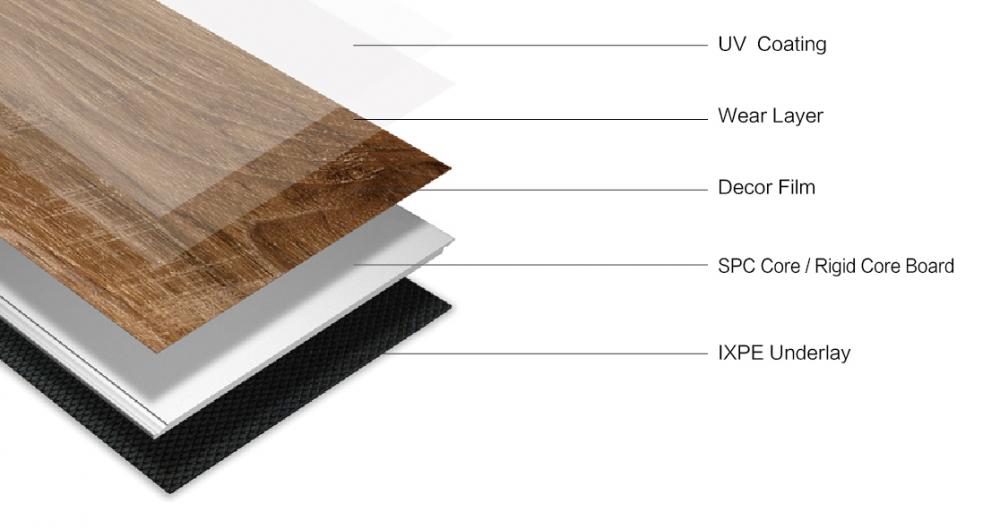

STRUCTURES

UV layer – to prevent fading, more wear-resistant

Wear Layer – to protect the PVC print film against scratches & stains

PVC Decorative layer – to show different patterns and natural wood effect

SPC Core – made by PVC resin, limestone powder and stabilizers etc.

IXPE Layer – Mute effect, comfortable feet feeling, better stability (OPTIONAL)

WHAT MACHINES FOR THE SPC FLOOR PRODUCTION

The SPC floor project machines include: Mixing system, Extrution line,UV coating machine, Slitting & Slotting machine, IXPE lamination machine and auto packing machine (Optional)

We provide the TURN-KEY SOLUTION-SPC Floor Extrusion production line and After-treatment machines.

We can design the factory layout according to your request.

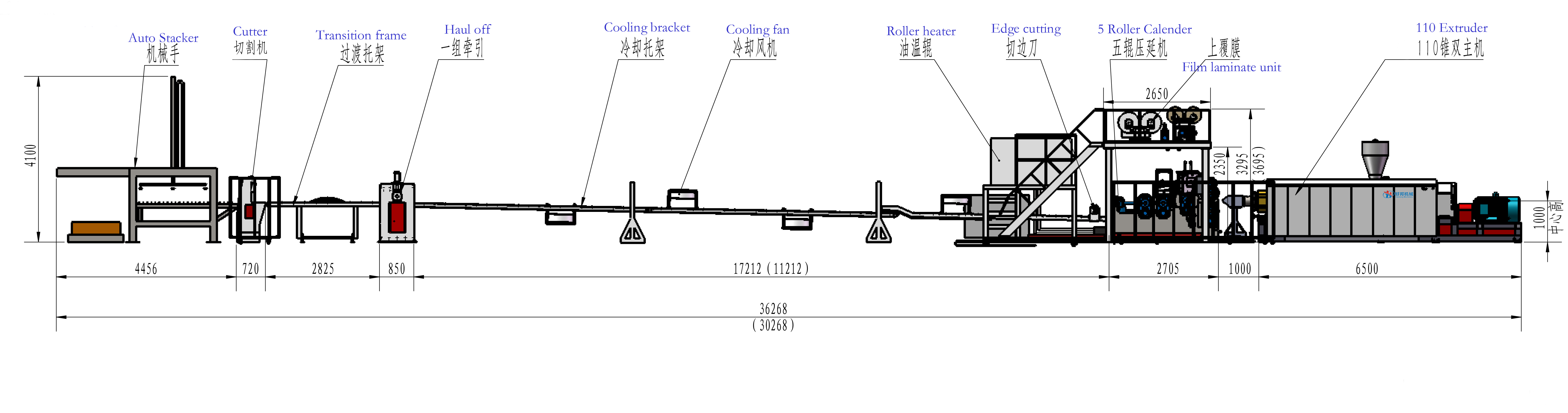

High capacity, high-performance Twin-Screw Extruder

Two types of machine for your option:

110/220 Conical twin screw extruder (Normally Capacity is about 28-32 Tons/day)

135/30 Parallel twin screw extruder (Normally Capacity is about 38-40 Tons/day)

The daily production capacity depends on the raw material and operation skills.

Automatic loading and feeding system

Put the raw materials that mixed by the mixer into the silo, and the raw materials will get up to the hopper by auto.

Different types: 500/1000L, 1000/3000L, 1500/6000L for your choice.

Lamination platform

The function of all of rollers are moulding, planishing and keep the board has the average thickness. The roller on the bottom is for the anti-skid design on the back side. The rollers surface in the middle are smooth, the main function of them are moulding and planishing. On the top of the roller is for the good-looking design on the front side. You can see the stairs and the platform, they are for lamination. Workers can go upstairs to change the film.

The arrange of roller can be vertical , horizontal or free adjusting type, which can give more selection basing on different thickness of sheet.

Haul Off & Cutting Machine

The double loop cooling system and mould temperature controller are adopted to control press-roller temperature, by which sheet thickness can be controlled accurately.

Auto Stacker

The automatic measuring meter instrument can set the length of sheet.

OTHER AFTER-TREATMENT MACHINES NEEDED

A. UV coating machines

B. Slitting and slotting machines

C. IXPE layer coating machines (OPTIONAL)

D. Packing machines (OPTIONAL)

Wuxi Haobang Machinery is the well-known plastic extrusion machine manufacturer & supplier for the SPC floor,WPC/PVC foam board and other plastics sheet, profile with more than 15 years `experience,we have professional developing team and mechanical designer and electrical engineer,and technical service team, excellent workers, responsible to every respected customer,.

Extrusion machines list:

1. SPC PVC LVT PP flooring production line

2. PVC WPC foam board, PVC free foam sheet, advertisement board production line

3. PP,PE,ABS,PC,PMMA,PS sheet/board machine line

4. PC PP PVC Hollow sheet, roofing sheet production line

5. PVC profile, WPC profile production line

Welcome to visit our factory!

Looking forward to cooperating with you!

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.