PROFESSIONAL PVC SPC FLOOR MACHINE

Get Latest Price| Payment Type: | L/C,T/T |

| Incoterm: | FOB,CFR,CIF,EXW |

| Min. Order: | 1 Set/Sets |

| Transportation: | Ocean |

| Port: | SHANGHAI |

Mr. TONY

What can I do for you?

| Payment Type: | L/C,T/T |

| Incoterm: | FOB,CFR,CIF,EXW |

| Min. Order: | 1 Set/Sets |

| Transportation: | Ocean |

| Port: | SHANGHAI |

Model No.: HBP-135/30

Brand: HAOBANG

Product Type: PVC Board

Board Layers: Single Plate

Screw No.: Double-screw

Automation: Automatic

Computerized: Computerized

Certification: CE

Customized: Customized

Condition: New

HIGH PERFORMANCE SPC Floor Extrusion PROJECT

SPC FLOOR PRODUCT INTRODUCTION

SPC FLOORING (Stone Plastic Composite) is one of the latest type decoration material in office building and home decoration design industry this year, it consists of PVC resin, limestone powder and stabilizers to create an extremely durable core, then laminate the PVC pattern film and wear layer by the 5 rollers calendar. SPC flooring is 100% waterproof and has an enhanced stability structure.

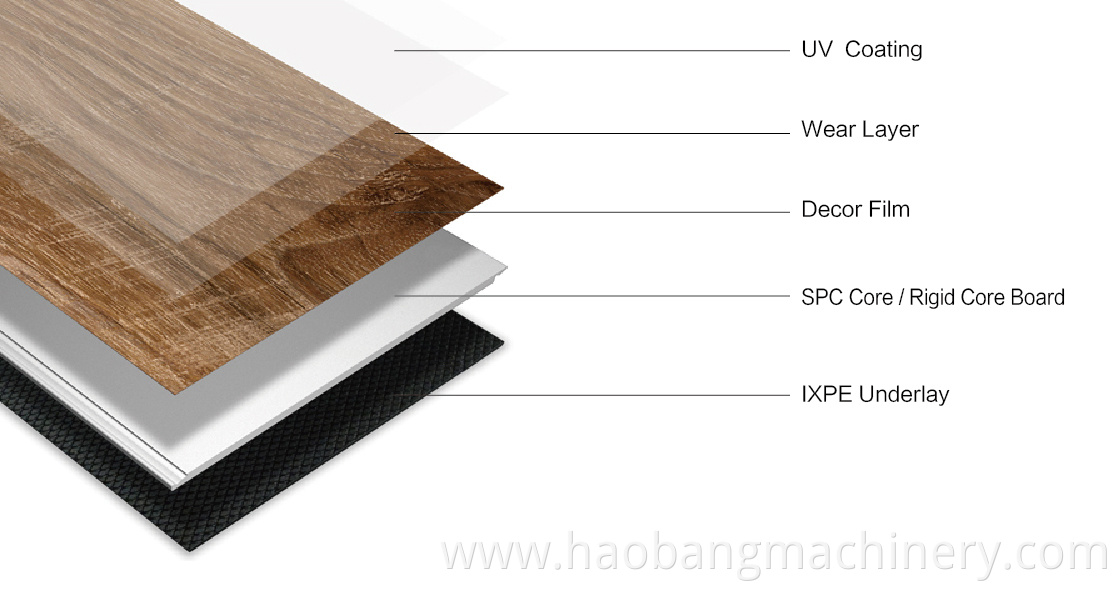

SPC FLOOR STRUCTURES

UV layer – to prevent fading, more wear-resistant

Wear Layer – to protect the PVC print film against scratches & stains

PVC Decorative layer – to show different patterns and natural wood effect

SPC Core – made by PVC resin, limestone powder and stabilizers etc.

IXPE Layer – Mute effect, comfortable feet feeling, better stability

SPC FLOOR ADVANTAGES

Waterproof

Anti-termite

Easy to maintain

Scratch resistant

Easy to install

Easy to clean

Non-slip

Anti-fouling

SPC FLOOR SIZE & APPLICATIONS

Width: 975mm, 1220mm

Thickness: 2-8mm

PROFESSIONAL EXTRUSION MACHINE MANUFACTURER AND SUPPLIER IN CHINA.

We provide the TURN-KEY SOLUTION--complete production line for SPC floor and After-treatment machines.

We can design the factory layout according to your request.

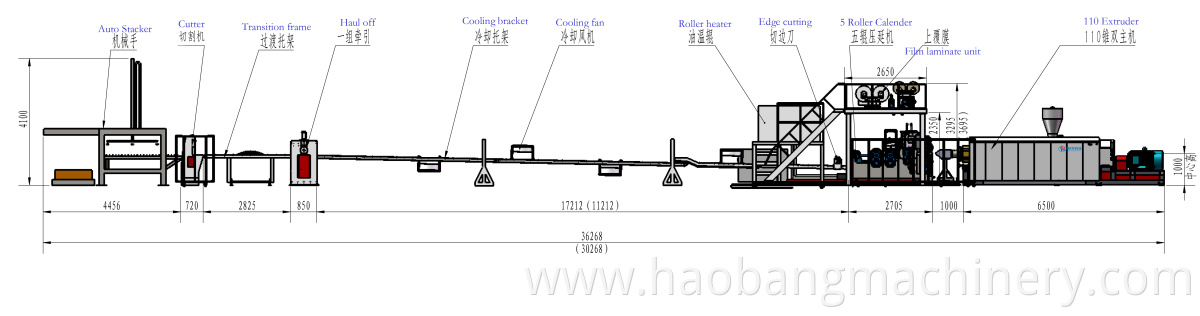

WHAT MACHINES FOR THE SPC FLOOR PRODUCTION?

1. High capacity, high-performance Twin-Screw Extruder

Two types of machine for your option:

110/220 Conical twin screw extruder (Normally Capacity is about 28-32 Tons/day)

135/30 Parallel twin screw extruder (Normally Capacity is about 38-40 Tons/day)

The daily production capacity depends on the raw material and operation skills.

2. Four / Five / Six Rollers Calender with Online lamination system

These days we release the 3rd generation EIR system

(more than 95% rate of qualified products, less than 2 mm error)

Lamination unit

3. Haul Off & Cutting Machine

4. Auto Stacker

5. Auxiliary machine: Raw material Mixer

Different types: 500/1000L, 1000/3000L, 1500/6000L for your choice.

6. OTHER AFTER-TREATMENT MACHINES NEEDED

A. UV coating machines

B. Slitting and slotting machines

C. IXPE layer coating machines (OPTIONAL)

D. Packing machines

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.